Wastewater Treatment

CONTACT US :

E-mail: info.in@bipurewater.com

Phone: + 91 80-4001 6032

BIPW primarily offers and uses the following technologies for wastewater treatment:

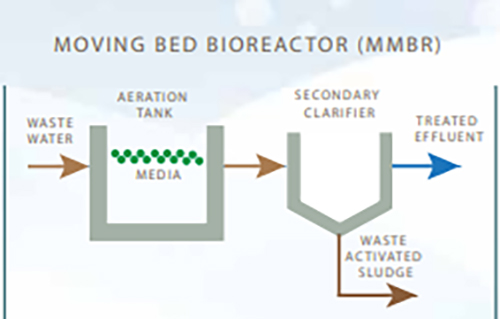

- Moving Bed Biological Reactor (MBBR)

- Membrane Bioreactor (MBR)

- Membrane filtration for tertiary treatment

- Advanced Oxidation Process (BIPERLIMINATE)

The above technologies may also be used for plants for Water Reuse application like:

- Agriculture Irrigation for crops and nurseries

- Landscape Irrigation for parks, golf course, residential buildings etc.

- Industrial recycling for cooling towers, boiler feed, process water etc.

- Desalination for water recovery from seawater

ADVANTAGES

- Least cost upgrading of existing wastewater treatment plants

- High quality effluent: total suspended solids ≤ 15 mg/L, BOD5 ≤ 15 mg/L, nutrient removal

- Better control of sludge bulking

- Greater biomass resulting in accelerated treatment with compact footprint

- Less waste sludge

- Less solids loading on the secondary Clarifier

- Has minimal operational requirements

- Reduces operating and maintaining costs

- Resilient to process upsets from toxicity

- Choice of packaged, container, or modular system

The BIPW-MBR is a high-performance membrane bioreactor which allows high biomass concentration (MLS 8000-160000 mg/L), with a small footprint. It is very resilient to changes or source water variability and will operate reliably under these conditions. No backflush or chemical maintenance is required and no entry into tanks is required for maintenance. BI-MBRs can be used for both domestic and industrial wastewater or mixed streams.

Membrane bioreactors (MBR) are very effective at treating variable wastewaters containing sewage and industrial effluent, which are typical in India. The resulting filtrate is such a high quality that it can be reused for industrial processes or for irrigation. If a UV unit or chlorination disinfection is added to the BI-MBR, then the filtrate becomes drinkable water.

Membrane Bioreactors combine conventional activated sludge treatment with membrane filtration, in a compact footprint, to produce water to global standards.

BI-MBR systems are designed in Canada and built in India to BI Pure Water standards, in containers or on skids, tested, and delivered ready to install and for quick deployment.

Sludge handling with this system is reduced compared to other MBRs. Dewatered sludge can be spread on fields, recovering nitrogen and phosphorus, or mixed into compost.

Advantages of MBR

- High biomass concentration (MLSS 8000-16000 mg/L) thus high loading rate and small footprint

- Resilient to changes or variability

- Consistent reusable effluent quality

- For both domestic and industrial wastewater treatment

- Low sludge yield so less sludge handling

- No backflush or chemical enhanced maintenance required

- Simple operation and maintenance

- Easy and simple for start-up

- Flexible system design

- Available as modular packages or on-site built systems

CONTACT US :

E-mail: info.in@bipurewater.com

Phone: + 91 80-4001 6032